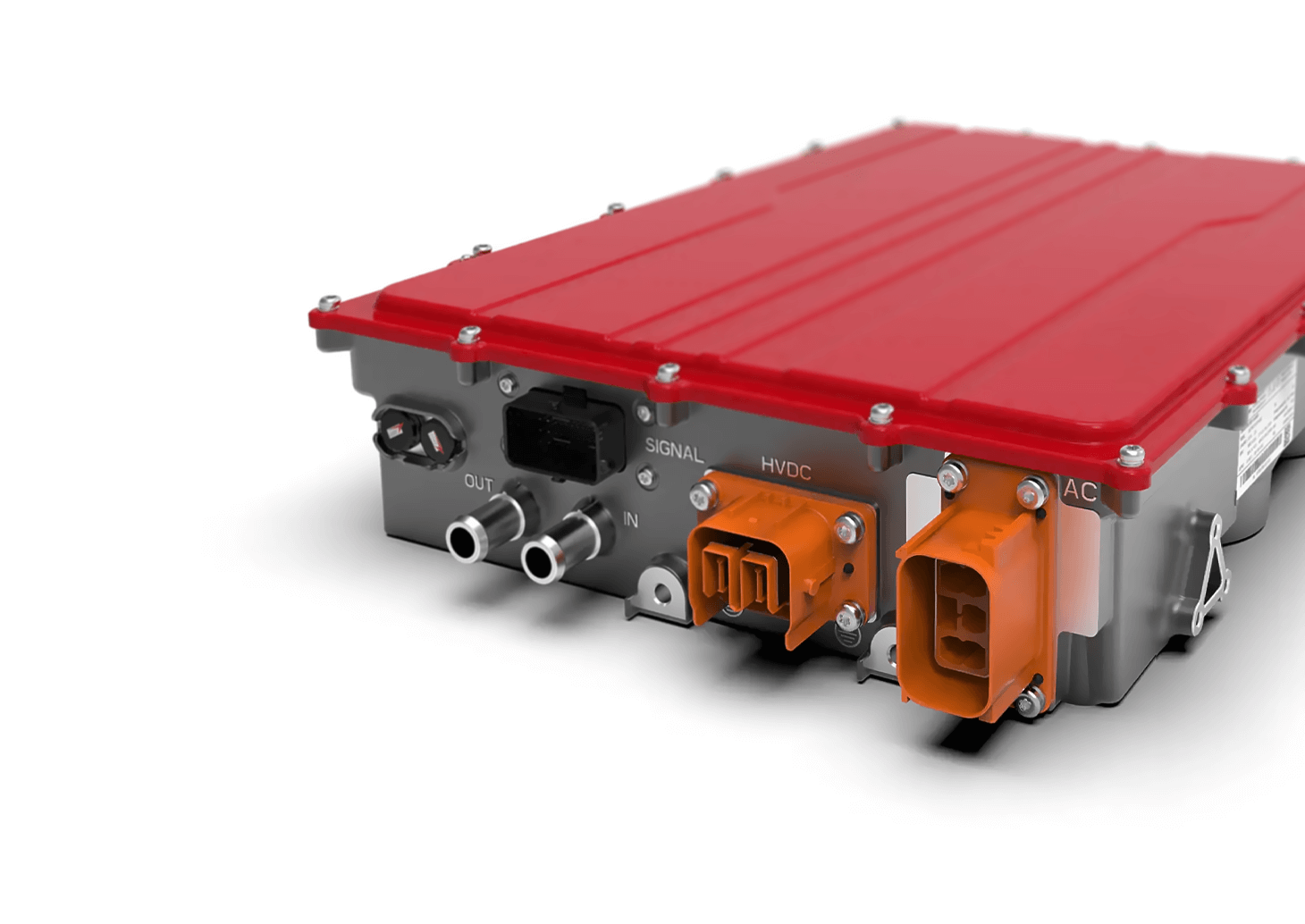

On-Board Charger

Advancing On-Board Charger Performance

with Real-Time Simulation

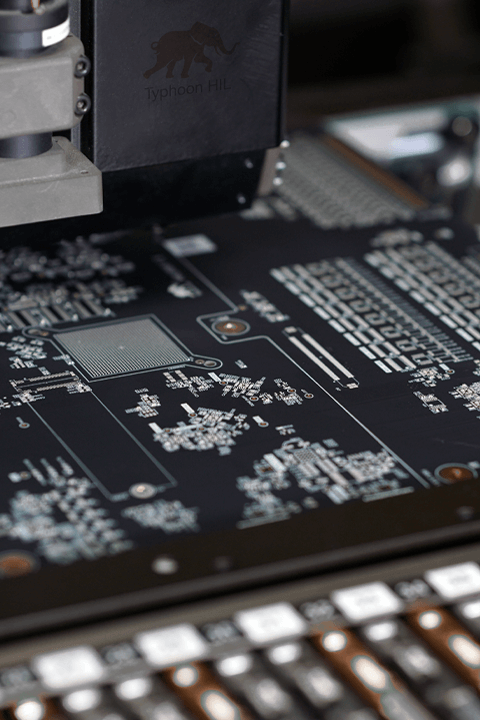

As electric vehicle (EV) technology evolves, the efficiency and reliability of on-board chargers (OBCs) are crucial to vehicle performance and user satisfaction. The challenge lies in accurately modeling and testing Power factor correction (PFC) front-end topologies and DC-DC converter stages under real-world conditions. Engineers must address variable grid conditions, electromagnetic interference, and design constraints while ensuring optimal energy conversion. Typhoon HIL’s ultra-high-fidelity real-time simulation platform provides a seamless solution to these challenges, enabling comprehensive testing and validation of OBC designs with unparalleled precision and efficiency.

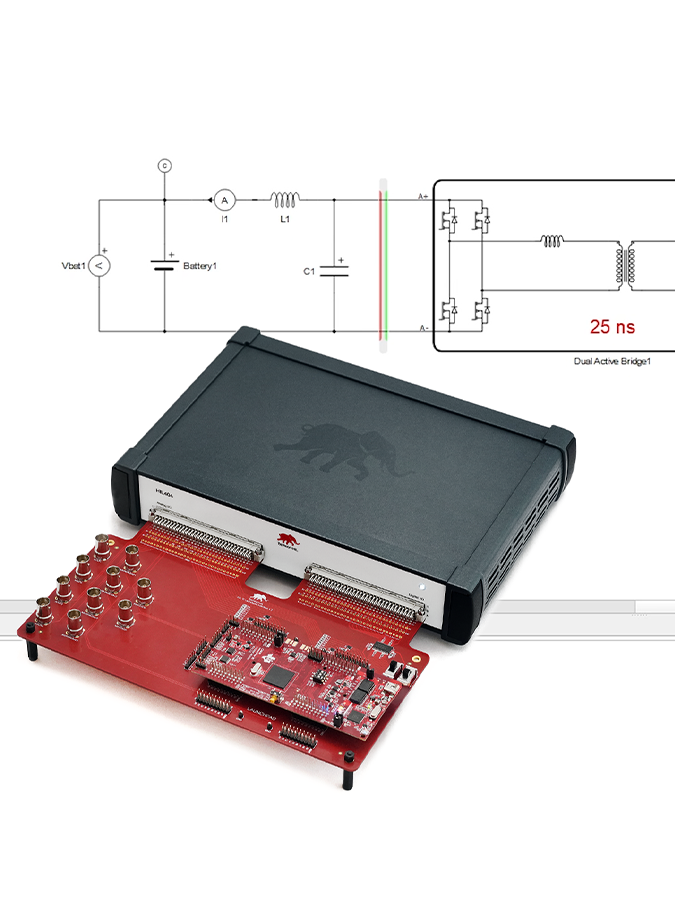

High-Fidelity PFC Front-End Simulation

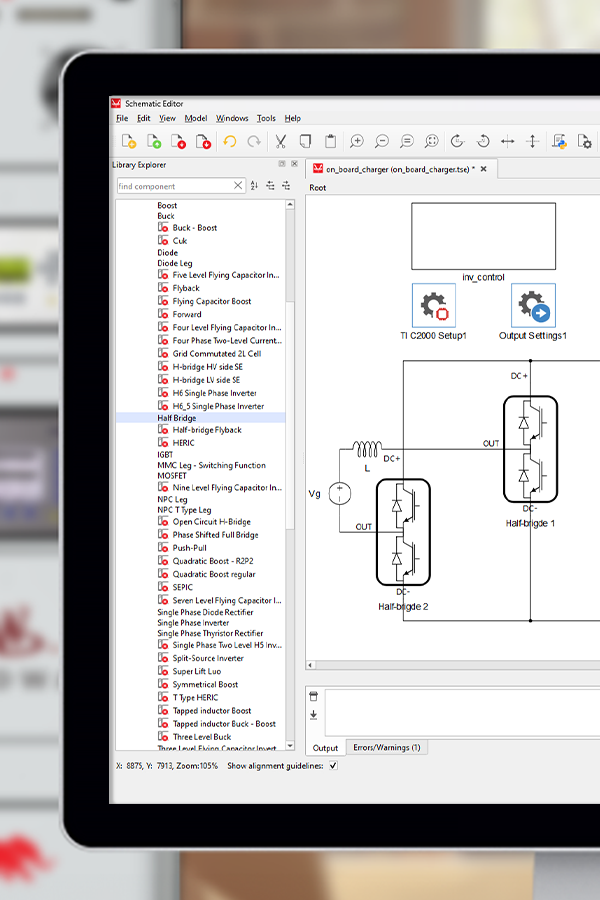

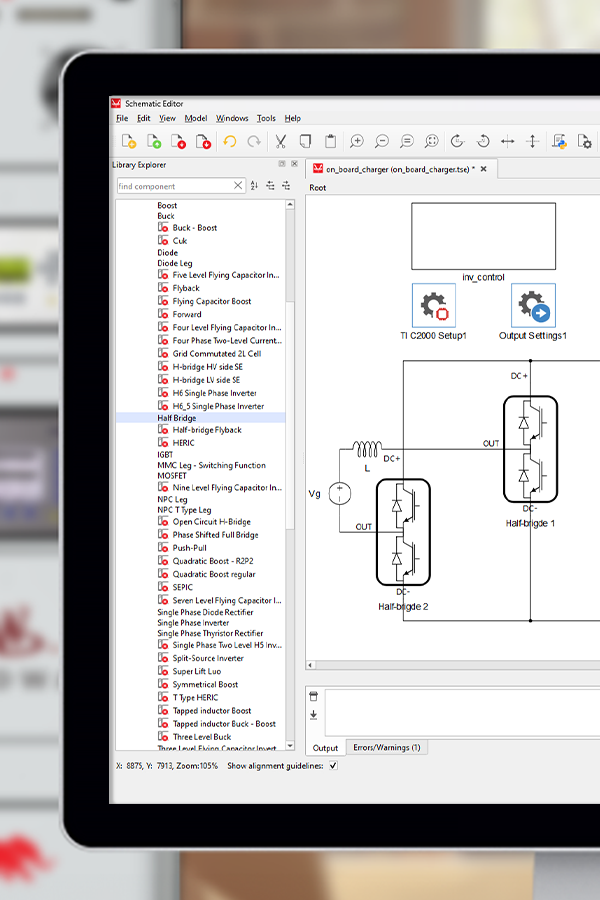

Typhoon HIL’s solutions empower engineers to simulate and validate a broad range of PFC front-end topologies, including single-phase and three-phase configurations. With an extensive library of rectifier and active power factor correction (APFC) models—featuring totem-pole, Vienna, and other advanced rectifier topologies—the platform facilitates real-time, high-fidelity testing of grid-connected OBCs.

Engineers can assess system responses to disturbances, voltage sags, and frequency variations, ensuring robust grid compliance. The software’s intuitive workflow and seamless hardware integration streamline design iterations, reducing development time and enhancing efficiency.

Comprehensive DC-DC Converter Support

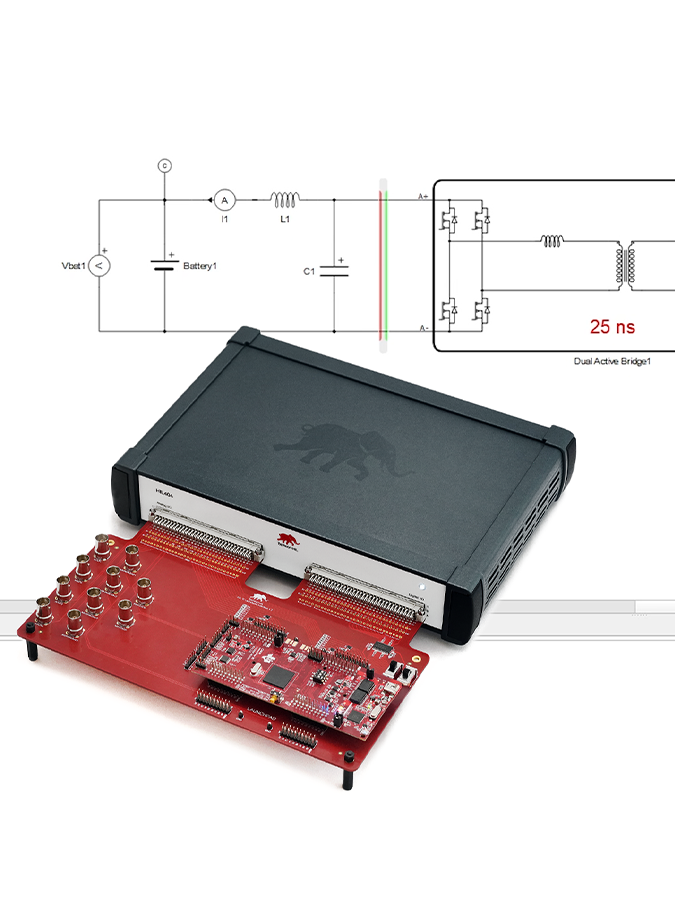

The second stage of an on-board charger, the DC-DC conversion, plays a pivotal role in delivering efficient and stable power to the vehicle’s battery. Typhoon HIL provides a versatile environment for testing various DC-DC converter topologies, including resonant and dual-active bridge designs. With its industry-leading enhanced resolution solver, offering higher accuracy, faster computation, and a 25 ns resolution for DC-DC converter simulation, engineers gain deeper insights into switching behavior and transient responses. This level of precision ensures that OBC designs meet the highest standards of efficiency, reliability, and safety while minimizing design risks and accelerating time to market.