Introduction

If we didn’t have this, we’d be stuck using a platform that we couldn’t change and therefore optimize. It really helps with confidence.

Solon Mardapittas

CTO

Powerstar

For this next spotlight, we got a chance to speak with Powerstar’s CTO, Solon Mardapittas, on developing Powerstar’s intelligent energy management system (EMS) with real-time Hardware-in-the-Loop (HIL) technology.

Based in the UK, Powerstar’s integrated energy system combines its voltage optimization technology with energy storage solutions. This not only secures power but lowers energy costs and provides demand-side response services to the grid.

Here is the insightful interview with Solon Mardapittas on Powerstar’s rigorous quality assurance process for its leading-edge technology:

Challenge 1 | Simulate Different Types of Loads and Generation

What are the major challenges smart inverter manufacturers experience when developing and testing inverter controls?

Solon: We’re looking at network resilience for our demand side customers, where we are creating a UPS-type storage system to assist against any voltage dips and transient events that may affect the load downstream.

We cannot be interfering with our clients’ existing generators and loads because a lot of our clients are critical manufacturers and require 24/7 autonomy.

It gets quite complicated because in most cases, there are hundreds of different types of loads and numerous types of generation that already exist on site.

This means running considerable simulations to make sure that the changeovers from grid to battery and synchronization are all within the times required for the load not to see the effect.

How did Powerstar use HIL technology to design and test its EMS controls technology?

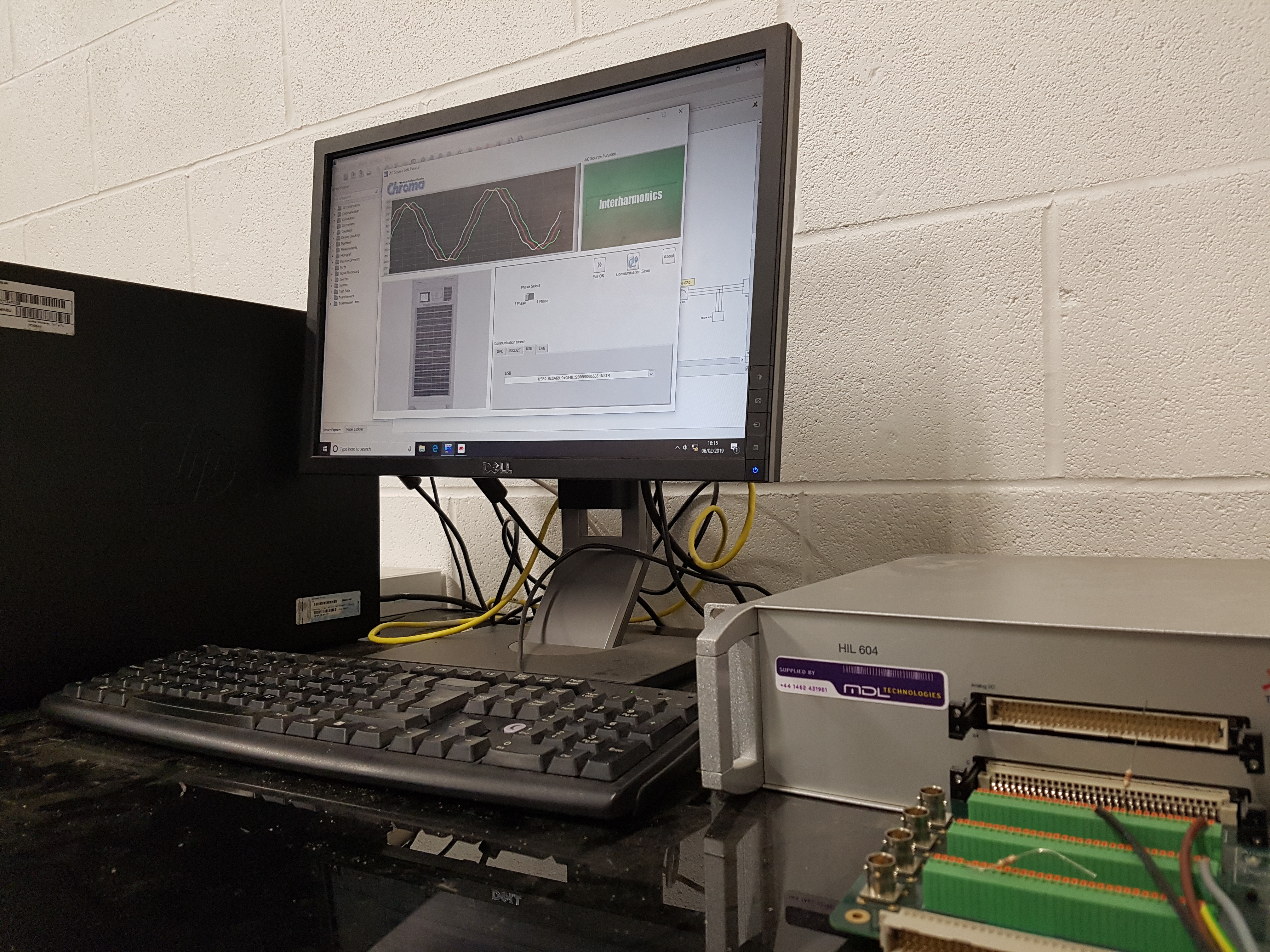

Solon: We used Typhoon HIL to create scenarios that we would expect from the grid. If the client is observing a certain event on the network then we can recreate it in HIL.

We’ve managed to create our own test documentation and models. This includes being able to synthesize virtual current flow, full contribution of the network, and grid impedance.

We’ve been able to simulate a microgrid and see how our inverter behaves within the network.

So Typhoon HIL has fundamentally helped with our product line.

Challenge 2 | Building a Physical Network is Costly

How were you able to recreate and predict outcomes that you see in the field using HIL?

Solon: A test scenario with pure hardware is extremely expensive and difficult to build. The idea of creating a test bed for every single type of system we sell is not feasible in a commercial space.

The way we use the Typhoon HIL is to create our customer’s network.

So we request information from the client and they send us the information, then we run an optimization strategy through HIL.

Solon: This allows us to effectively run scripts to see how they all interact together. Once we’ve confirmed that optimization strategy, we download it onto our EMS and then use that as a commercial energy management system for the site.

Can you tell me which tests were really the most time-consuming and most expensive to do?

Solon: When we’re looking at pairing UPS’s ability with demand response, we would like to make sure that we’re available as an asset to the network at all times. We have an availability clause within our performance contract with the client which means that we have to be available approximately 98% of the time.

If we create a model or create a loss of mains detection methodology that is too sensitive and we spend all the time in island mode, we cannot provide those services as a promised.

Solon: Instead, when there’s an outage event, we’d cover the load before the outage gets to it. But at the same time, we’re not nuisance stripping all the time by being in island mode and not being able to run those frequency response services or other services for the client.

Solution 1 | Model Microgrids in HIL Simulations

What are the main benefits of HIL technology for Powerstar’s quality assurance process?

Solon: I would say the primary benefits from the HIL is that we can create a network. In other models you have individual parts, so you have nodes here and there. What’s difficult is bringing them together into a network or a microgrid.

The Typhoon HIL allows us to take various widgets and modules to create a full map of interactions and see how all it all interfaces together.

Solon: The knowledge base from the Typhoon’s side is constantly being updated including the back end, what storage is available, what inverter ranges are available, and what the characteristics of those are. And we don’t have to concern ourselves too much with the depths of each individual node.

Solution 2 | Build a Virtual Setup for Client Demonstrations

How quickly were you able to support client requests for unique product functions?

Solon: The HIL helps us create the model we want. Now that shaves off an enormous amount of time especially when it comes to optimization. We can effectively do it with minimal cost on the client side. So they can say, we want this feature. Okay, fine, then we’ll create it virtually. We don’t have to do a physical test setup for this especially if we’re on the optimization side.

We can prove it mathematically that it works as opposed to spending money trying to create a test demo setup and only partially being able to show what we can do.

How easily can you go back and make changes to your HIL models?

Solon: It’s quite easy to make changes in those models by entering different characteristics into the grid. We could say, “We’ve actually got more harmonics on the grid than we thought.” Or the load is lagging for example. If there are inductive elements and other elements that we haven’t taken into account or haven’t fully realized, then we can add them.

If we’re seeing continuous voltage dips we would run approximately a hundred tests and make sure that we’re dealing without making huge changes to our hardware.

Solution 3 | Accelerate Testing with Test Automation

How were you able to do some automated testing with HIL technology to speed up the process?

Solon: We automate the testing through the HIL and the emulator for our voltage optimization range. We created test scripts using the Typhoon HIL of various voltage changes on the network which increased the ability for us to test units in terms of speed.

We’re actually able to get two units out for the one we had in before.

Conclusion | HIL is Excellent

What have you discovered about using HIL that surprised you the most?

It’s the ability to go back to the Typhoon engineers who created the backend platform and customize these modules that helps our testing.

Solon: If we didn’t have this, we’d be stuck using a platform that we couldn’t change and therefore optimize. It really helps with confidence.

One word to describe your experience with HIL?

Solon: It’s been excellent.

Credits

Author | Samantha Bruce

Visuals | Powerstar

Editor | Debora Santo