Project Objectives | PANDA Project Supports Transport Electrification

The increase in production and sales of Electric Vehicles (EVs) is forcing the automotive industry to rethink its development process. Traditionally, engines and transmissions are developed independently and delivered to car manufacturers for assembly. In electric powertrains, due to complex integration, this is not ideal, and a fundamental change is needed. The purpose of the PANDA project is to make this transition easier by developing a method that would organize and interconnect models for all EV components.

PANDA project objectives include:

- Design of an open organization methodology for virtual & real testing of EVs.

- Development of a multi-power open platform for Stand-Alone and Cloud-computing testing.

- Running virtual tests of reference EVs and real-time testing of selected subsystems.

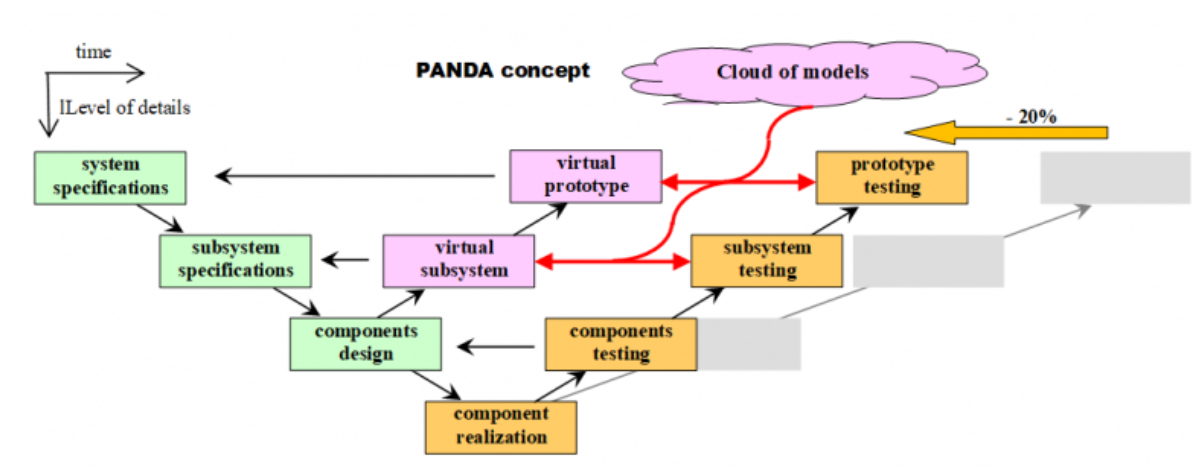

The ambition of PANDA is to reduce the time-to-market of EVs by 20% by changing the traditional V-model of product development with the so-called PANDA concept (see Fig. 1). This W-model would speed up the process of product development by adding a virtual validation axis.

Video Interview | Hear About the Project from Dr. Ronan German

In the video above, Dr. German from the University of Lille tells us how much the EV development and integration process can be improved using the W-model methodology, while the video below showcases the highlights from the PANDA Project Final Event. Watch the videos to learn more.

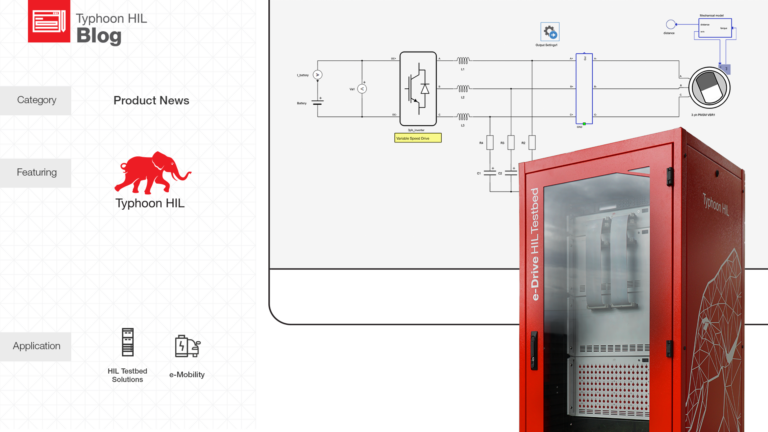

HIL Testbed | Typhoon HIL as a Part of an Integrated Testing Solution

A key outcome of the project was developing an integrated cloud-based power hardware-in-the-loop (P-HIL) testing solution. To make these cloud-based tests work in real-time, hardware electronics are needed on the ground to ensure the equipment works safely from microsecond to microsecond. For this, Typhoon HIL was the validation partner of choice. The process begins with downloading the complete vehicle model into the Typhoon HIL environment from the SIEMENS Amesim cloud. The setup is then connected through a HIL Connect interface, and after selecting the desired drive cycle, testing can start.

The universal Typhoon HIL interface solution (HIL Connect) is made for connection with protection relays in power electronics. For this project, the HIL Connect was optimized for the automotive industry and interconnection with other automotive testing solutions.

Battery Integration | Reliable and Flexible Full-Vehicle Testing

In EVs, testing battery performance under real conditions is vital to ensuring that the vehicle performs as intended on the road. Within the PANDA project, this meant testing a real EV battery pack in both standalone and vehicle prototype tests. Typhoon HIL testbeds were used to emulate the full vehicle model in real time and confirm that the battery system performed within the required specifications. Replicating the tests with a real vehicle yielded the same results.

With a full vehicle model using the EMR framework, downloadable for free for Typhoon HIL software, a full vehicle model can be run using compatible black box models provided by manufacturers of individual systems. This means more flexibility in how you test, and more reliability in integration tests when suppliers want to remain protective of their system performance.

Project Partners | Meet the Names Behind the Project

What is very rewarding and motivating is to be part of something bigger than the project itself. We can say that at our level, we are contributing to the energy transition and to the reduction of gas emissions and greenhouse effect by accelerating the manufacturing process of electric vehicles.

Alain Bouscayrol

Head of the Control Team of L2EP

The University of Lille

Industry partners | Siemens, Valeo, TÜV SÜD Battery Testing GmbH, Renault Technologie Roumanie

Research partners | University of Lille, Vrije University Brussels (VUB), University of Technology of Cluj-Napoca (UTCN), University Burgundy Franche-Comté (UBFC)

SME partners | Uniresearch, Blueways International, Typhoon HIL

Credits

Authors | Vuk Maletin, Sergio Costa, Debora Santo

Visuals | Karl Mickei, PANDA Project

Editor | Debora Santo

The PANDA project has received funding from the European Union’s Horizon 2020 research and innovation program under Grant Agreement No 824256. Read more on the projects’s CORDIS page.