Introduction

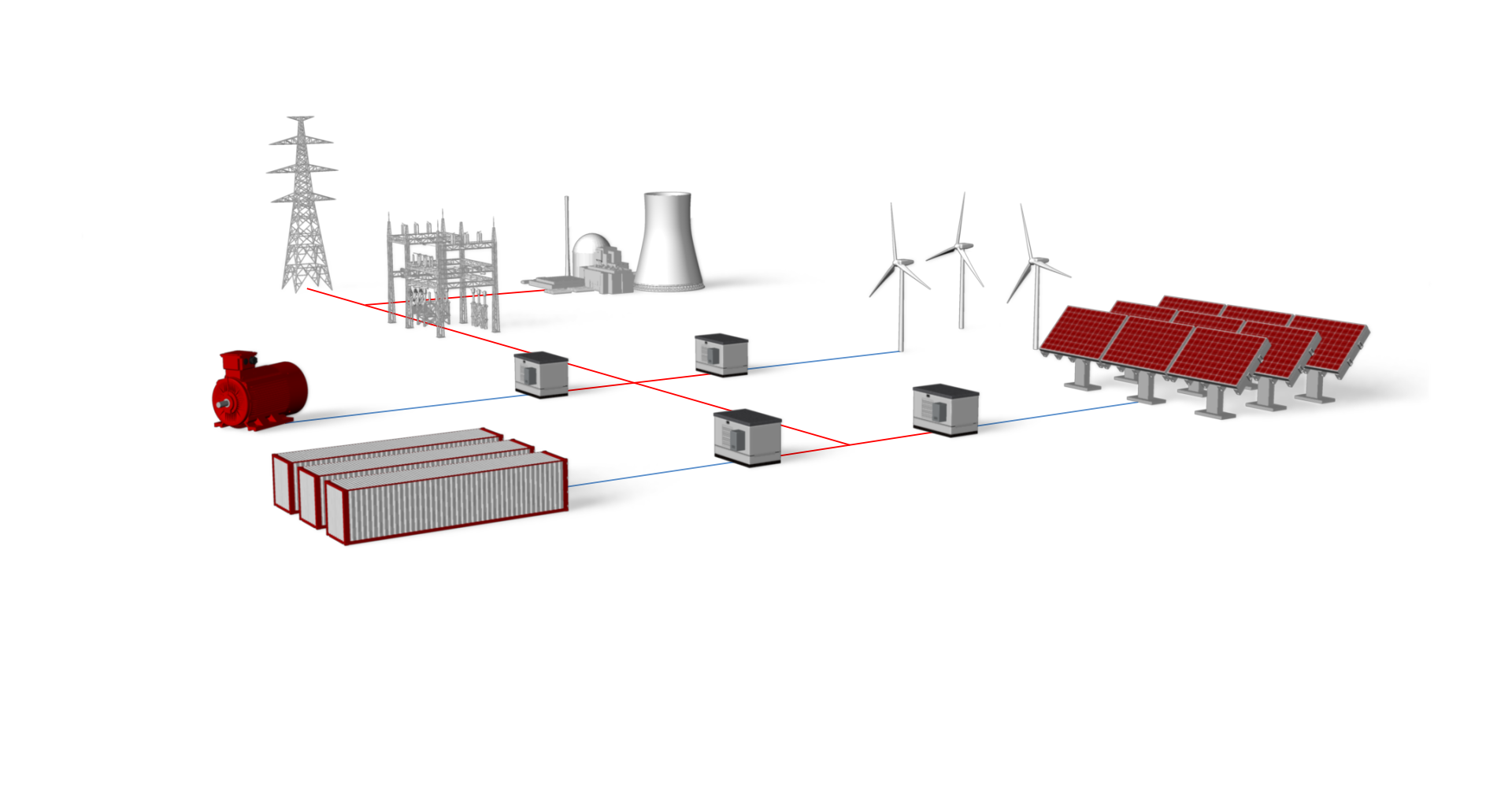

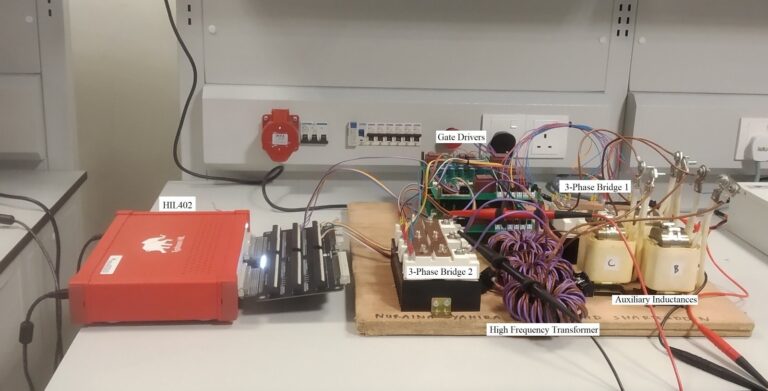

This year at the Microgrid & DER Controller Symposium, organized by the Massachusetts Clean Energy Center and the MIT Lincoln Laboratory, Typhoon HIL will be presenting center stage two live Microgrid HIL Testbed demos using the ultra-high fidelity controller Hardware in the Loop (HIL) interfaced with real industrial controllers.

We will demo both Eaton and GE microgrid controllers, in action, directly interfaced with Microgrid HIL Testbed and controlling a complex microgrid controller HIL real-time simulation comprising 3 feeders with 24 busses, one diesel genset, one natural gas genset with combined heat and power, battery storage, PV inverter, and multiple loads running in real-time.

To make it even more interesting, we will be injecting random faults; dispatching DMS requests to the microgrid controller to export active/reactive power, and to island; blackstarting the microgrid and all this while monitoring the microgrid “pulse” and measuring and streaming all the performance parameters in real-time.

As we are working with vendors to integrate their controllers with Microgrid HIL Testbed, to put it to the ultimate performance test, we are experiencing first-hand how challenging and grueling the task it is to commission and test microgrids and microgrid controllers. Even in this day and age.

To complicate things even more, the majority of microgrid projects are so-called “brownfield” projects that are actually upgrades and retrofits of the existing power systems. Getting legacy and new microgrid assets to work together and communicate in such heterogeneous microgrids is a tall order.

During the microgrid controller design, integration, and commissioning there are five grand challenges, as we see them today, that need to be overcome:

- Configuring and testing communications between microgrid controller and DERs-relays

- Configuring and testing protection

- DER controller configuring and testing

- Islanded mode power quality and system stability

- Certification of microgrids and microgrid controllers

Without ultra-high fidelity controller HIL simulators, microgrid controller vendors had no other choice than to jump directly from the design phase to onsite commissioning and testing. When this commissioning is a retrofit job, the project cost and time exponentially explode.

Controller Hardware in the Loop accelerates testing, commissioning, and pre-certifying of microgrids and solves these 5 Grand Microgrid Challenges. Indeed, this is what MIT Lincoln Laboratory Microgrid & DER Controller Symposium is demonstrating with Hardware in the Loop HIL Testbed and a spectrum of microgrid controller vendors.

Communications testing

A variety of communications protocols and no clear standardization in the field of microgrid communications require significant expertise and time just to get the microgrid controller to talk to all the assets. Even when all the nodes talk the same “language,” e.g. Modbus, it takes a tremendous amount of time to set up all the right registers, addresses, modes, etc. Now, if you are doing this in the field with limited patience for reading manuals while the DERs are pushing power it is an extremely risky job.

Fortunately, Microgrid Hardware in the Loop simulation provides ultra-high fidelity communication models for different DERs and relays that enable plugging the microgrid controller into HIL and configuring communications using a virtual device. Incredible savings in time and money can be realized when this step can be done in the comfort of an office with a desktop HIL directly communicating with a microgrid controller.

Protection

Adjusting protection and protection coordination is a complex task, especially for islanded operation and with large penetration of power electronics converters. In addition, more networked topologies that are starting to replace traditional radial networks pose an additional set of challenges, including the reconfigurability of network topology.

Controller Hardware in the loop simulation provides a complete environment to test all the protection and protection coordination for all different fault scenarios. In addition, controller HIL provides the flexibility to start with high-fidelity relay models and then migrate to testing with real relays in the loop with the simulation.

DER controller configuring and testing

Microgrid projects often need to integrate heterogeneous DERs from different manufacturers into a functional unit. Configuring and tuning inverters and gensets for a particular microgrid architecture can be a daunting task.

Controller Hardware in the Loop simulation where DER controllers are integrated into the testbed enables comfortable configuration and parameter tuning process, without the need to go into the field and perform full power tests. The time and money savings when this is done in the comfort of an office with a desktop HIL interfaced to microgrid controller and DER controllers are tremendous. Even if particular controller hardware is not integrated into the testbed one can use controller models to tune and test a number of parameters that will be used as a solid starting point in the field.

Power quality and system stability in islanded mode

While microgrid controls in grid-tied operation is challenging, the real test of microgrid controller capabilities is its ability to seamlessly transition from grid-tied to islanded mode and back, and its ability to provide power quality including tight frequency and voltage control. Furthermore, islanded operation is paramount.

Certification of microgrid controllers

While Controller Hardware in the Loop (HIL) pre-certification of inverter based DERs (solar and wind) is burgeoning, microgrid testing is still in its infancy. In addition, microgrid standardization is in its infancy. IEEE1547.4 is starting to outline good practices and hopefully new revision of IEEE1547 will cover more microgrid standardization the field is still largely uncharted.

The emerging standards for microgrids will require LVRT/HVRT, LFRT/HFRT, and grid support functions, similar to DERs, and the only way to systematically test these will be with cHIL. Field testing, for all different microgrid configurations at MegaWatt power levels is just not an option. Controller Hardware in the Loop will become an irreplaceable tool for testing and certification of Microgrids.

Credits

Author | Ivan Celanovic

Visuals | Typhoon HIL

Editor | Debora Santo