By deploying a 30 MW/ 8 MWh battery energy storage system on a long radial feeder line, the project has reduced unplanned outages from eight hours to under 30 minutes for the customers connected to the network.

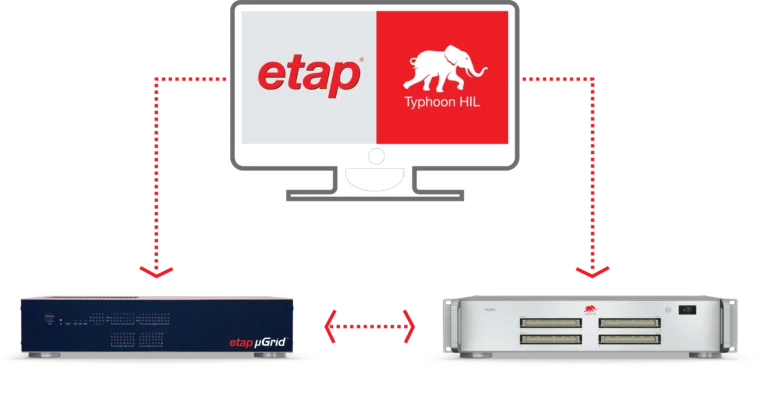

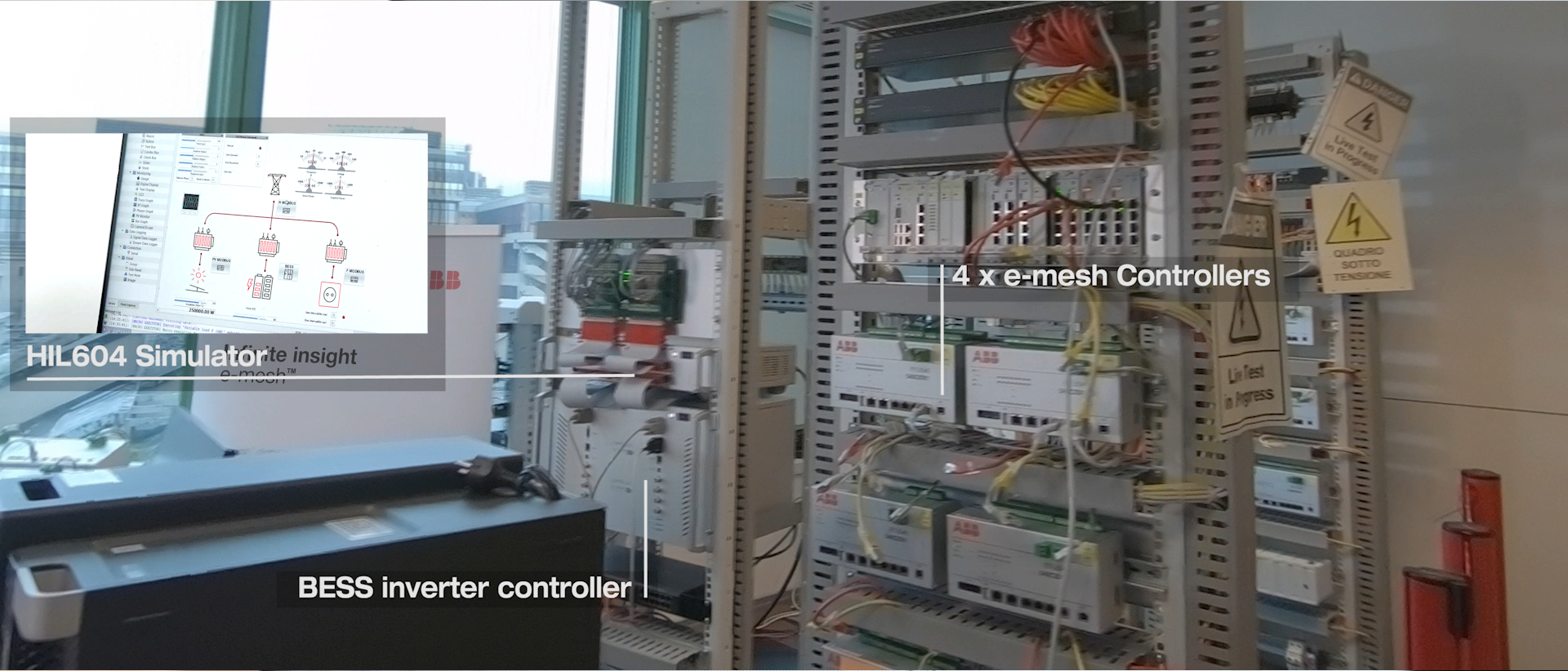

But the wealth of experience is not enough; Hitachi Energy needs to prepare for the unknown. As such, they pair these capabilities with HIL modeling and testing to ensure microgrids are the right fit for the market. This starts from day one; simulations are used in the creation of the business case for the customer. Real-time HIL platforms help to optimize the design and service offerings for Hitachi Energy’s portfolio.

Being able to test the desired functional concepts of a microgrid prior to deployment is a major factor in de-risking a project.

Tilo Buehler

Global Product Manager Grid Edge Solutions Team

Hitachi Energy

State-of-the-art modeling and simulation were used for the ESCRI-SA Dalrymple project in Australia. By deploying a 30 MW/ 8 MWh battery energy storage system on a long radial feeder line, the project has reduced wind production curtailment from the 91 MW Wattle Point wind farm. It has also reduced unplanned outages from eight hours to under 30 minutes for the customers connected to the network. In the first six months of operation, it has created over AUS $50 million in revenue from frequency control ancillary services. The success of the project was enabled by the use of HIL testing.

Hitachi Energy also applies HIL testing to comply with certification and standards, such as grid codes, prior to deployment. Coupling a battery energy storage converter controller with a real-time HIL system allows the team to check its behavior against country-specific test cases. A large number of tests are run against flexible conditions to meet the requirements of a specific customer or country.

This is a great benefit in managing timescales, managing cost of validating the system performance and thereby a benefit towards the certification.

Tilo Buehler

Global Product Manager Grid Edge Solutions Team

Hitachi Energy

Subscribe to blog updates in the top right

to be the first to receive the upcoming blogs by email.

Additional information: The full Special Report was originally published with Microgrid Knowledge as a 6-part series. You may follow the links to read the original publications on their website:

- Hardware in the Loop: Addressing the Challenges of Microgrid Systems Integration

- How to Validate a Microgrid Project

- Pros and Cons of Testing Methods to Validate Microgrid Designs

- How Hardware in the Loop Tests the Functionality of Microgrid Controllers

- Streamlining Microgrid Development with Model-Based Engineering

- How Does Hardware In the Loop Work in the Real World

Disclaimer l Hitachi Energy is formerly known as Hitachi ABB. In the original publication with Microgrid Knowledge, they appear under the name of Hitachi ABB, which the company carried at the time of publishing. The company name has been updated in this publication to match the current status.