The Industry Spotlight series features global leaders who are using model-based test solutions and Hardware-in-the-Loop (HIL) technology for their leading-edge projects in the power electronics and power systems industry.

Hitachi Energy is a pioneering technology leader in advanced automation systems and digital energy solutions for utilities, industry sectors, mobility, IT, cities, and remote communities.

In the first part of this two-part series, Tilo Buehler – Global Product Manager, Luca Cicognani – Strategic Partnerships Manager, and Michele Fusero – Senior R&D Engineer at the Grid Automation Business Unit, discuss the key advantages of Hitachi Energy e-mesh solutions.

Can you tell us about the Hitachi Energy e-mesh portfolio?

Tilo Buehler: The key trends that we see emerging are decentralization, decarbonization, and digitalization. These trends are pushing for technology that allows us to control assets more efficiently which is largely based on decentralized approaches.

Our e-mesh portfolio in Grid Edge Solutions is a digital concept that allows us to manage distributed energy resources from the device level through the systems control and all the way up to the industrial Internet of Things domain where we can then provide data that is generated by our devices such as asset performance, monitoring, and database benefits.

How does Hitachi Energy e-mesh provide value to their customers?

Luca Cicognani: Our customers require a couple of things: continuity in the electricity supply, reduced cost of the energy supply by maximizing the use of the renewable power plant, and a way to remote monitor and understand if the goal is achieved and how to improve it. So we are developing a solution that addresses microgrids, energy storage and automation, and control of distributed energy resources.

What does your team at Hitachi Energy do?

Michele Fusero: At Hitachi Energy, we work with Grid Edge Solutions, which normally apply to microgrids, distributed generation, and battery energy storage systems to make sure that all the assets in the microgrid are working in a coordinated way.

Luca Cicognani: The microgrid is putting storage together with traditional power generation as well as renewable power plants. The brain of this is the control system which optimizes the flow of the different assets in a way that the supply of electricity is stable and reliable.

The end-user can be a utility that has an issue in the network. And they want to have more stability in the grid. The end-user can be also a remote community. They want to have a stable, cheaper, and reliable source of energy based on a renewable power plant.

What are some of the key expectations from your customers?

Tilo Buehler: The key expectations from our customers are that the complex system configuration provides the system reliability and system resiliency as we promise to deliver in our e-mesh concept.

Luca Cicognani: In Norway, in a football arena, during a match when there is a peak of demand, the goal is to maximize the use of the photovoltaic power plant together with the storage system. And combining these assets with the availability of cheap energy in the network. Our e-mesh optimization solution can maximize the use of renewables when it is needed or sell to the market when there is an excess of production.

What are the key challenges to designing and testing e-mesh control solutions?

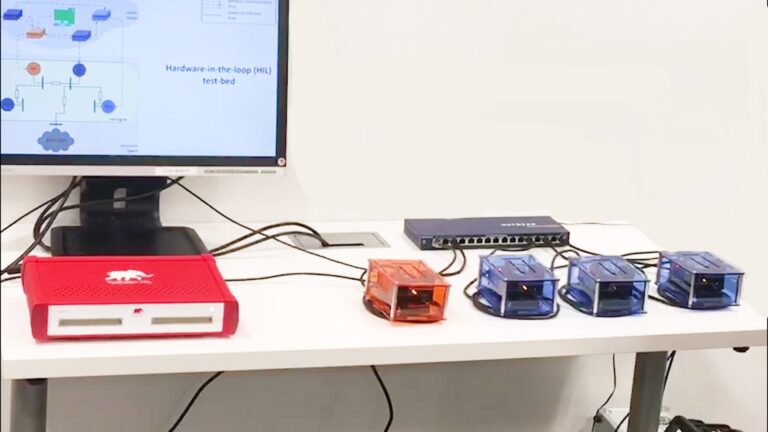

Michele Fusero: In a vertically integrated system, communication plays a key role because we have a distributed approach. All the controllers communicate with each other, with various devices in the field and with the SCADA. This implies a high number of signals to be transmitted and received from other devices.

Tilo Buehler: For us, that means we need to interface a lot of controllers in a complex system environment and do the development on those controller solutions in a cost-efficient and effective manner.