Introduction

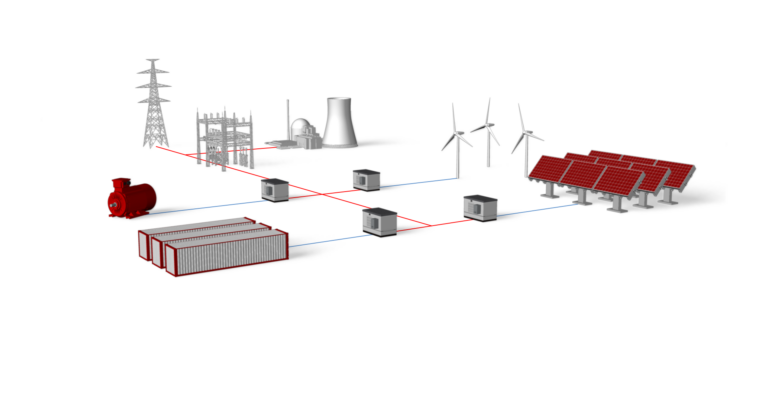

Seamlessly integrating a massive amount of energy storage into the national power grid is critical to the clean energy transition. That is the focus of IHI Terrasun Solutions (IHI Terrasun), a leading power plant software developer, battery energy storage system (BESS) integrator, and field services provider. IHI Terrasun began a partnership with Typhoon HIL in 2018 to ensure the entire BESS could be simulated and tested to avoid lengthy and costly in-field commissioning and service issues. IHI Terrasun’s work with Typhoon HIL is a model of collaboration, technical precision, and proactive testing that contributes to advancing the reliability and efficiency of energy storage.

IHI Terrasun sets itself apart by being battery and inverter-agnostic. The company can integrate one inverter/battery pair for a project and then switch manufacturers for another project, all the while using Typhoon HIL simulation systems to check interoperability with the power plant controller software. “We’re able to integrate, communicate, control, and test products from different OEMs to find the best equipment combination for a project rather than being bound by a single configuration that doesn’t necessarily provide the best solution for each project’s unique requirements,” said Jared Spence, Senior Business Manager, Systems Solutions at IHI Terrasun.

The Typhoon HIL Simulation hardware, software, and tools are extremely valuable for IHI Terrasun Solutions (IHI Terrasun) as they provide a means to quickly, safely, and cost effectively test Energy Storage Devices and Energy Storage Systems (ESS). IHI Terrasun can safely simulate failure cases on a Typhoon HIL System that would normally cause serious equipment damage on a real system and unsafe conditions for personnel. In using a Typhoon HIL Simulation System, IHI Terrasun can ensure through simulation and testing that our controls take the proper safety actions, log all of the data around the event, and report the situation to the appropriate people and entities.

Jim Cleveland

Senior Controls and QA manager

IHI Terrasun

Lowering Risks with Hardware-in-the-Loop Testing

IHI Terrasun developed the SAFEtm (Simulated Acceptance and Fault Emulation) program, an experience and data-driven multi-layer simulation process that at its core includes the Typhoon’s hardware-in-the-loop testbed. The process ensures that system components and software operate seamlessly. It also significantly lowers risks and reduces deployment and commissioning times.

The exhaustive test procedures developed by IHI Terrasun demonstrate the company’s ability to adapt to new hardware. IHI Terrasun also has a proprietary automation module integrated into the HIL test deployment which substantially speeds up variable testing on the systems.

“By performing critical system testing on a Typhoon HIL simulation system, IHI Terrasun can ensure that our controls take the proper safety actions, log the data around the safety events, and report appropriately,” said Jim Cleveland, Senior Manager of Controls Engineering and QA at IHI Terrasun. “We test as much as we can because we need to make sure that all the parts are going to work together when we commission the project.”

This proactive testing, using Typhoon HIL’s simulation environment, not only boosts customer confidence in the project but also accelerates commissioning and ensures consistency.

Simulating Potential Failures with Hardware-in-the-Loop Testing

In a simulated test environment, IHI Terrasun can create many different scenarios experienced by a battery system, power conversion system (inverter and/or converter), and control system overall. The company can monitor as simulated failures propagate through devices or software, such as a Battery Management System (BMS), or the power conversion system, and then monitor and measure the response from IHI Terrasun’s Power Plant Controller (PPC).

“One of the great advantages of using a Hardware-In-the-Loop (HIL) simulation environment is that it allows IHI to quickly and safely simulate failure conditions that would be extremely dangerous, such as: over and under temperature conditions, over current conditions, over-voltage conditions, ground faults, and phase-to-phase shorts. On real systems in a lab or in the field, these types of tests could absolutely lead to equipment damage and injuries but are safe to emulate within the simulation environment,” Cleveland said. “When testing failure conditions on lab systems or in the field, one must be very knowledgeable of the device and its impact on the entire system to avoid equipment damage, injuries, or grid events. With the Typhoon HIL system, we can safely simulate these and many more conditions and verify proper safety protocols and operations,” Cleveland said.

IHI Terrasun Adds Expertise to the Development of the IEEE2800 Standard

The Typhoon HIL system allows IHI Terrasun to check functional controller requirements for energy storage, ensuring that customers’ system performance aligns with the Institute of Electronics and Electrical Engineers (IEEE) standards such as IEEE 2800, which addresses interconnection and interoperability of inverter-based resources (IBRs) that are connected to transmission electric power systems.

The IEEE 2800 standard that is currently under development serves as a step in the evolution of standardization for energy storage (and large solar, which are both inverter-based systems) as the sector transitions from theoretical models and small projects to practical, operational systems catering to diverse grid management across the U.S.

As a member of the IEEE 2800.200 working group, Ray Saka, the VP of Business Strategy and Services at IHI Terrasun, has provided insights and expertise to influence the development process of the testing requirements for the new standard which involves compliance with grid stabilization features such as Active Power Control, Primary Frequency Response (PFR), Fast Frequency Response (FFR), Reactive Power Control, voltage regulation, and power factor control. Thanks to his work, IHI Terrasun has prepared simulation methodologies to not just meet the current expectations of developers but to also anticipate the adoption of IEEE 2800 requirements across different regions and ISOs (Independent System Operators). This foresight allows for predictive modeling of potential system changes and improved design and integration phases, which translates to robust and efficient real-world operations.

IHI Terrasun has over 60 operational projects across North America with a comprehensive understanding of the entire project lifecycle—from design and implementation through testing, commissioning, and sustainment. The company’s ability to integrate disparate components from various manufacturers into a cohesive operational system is successful because of the simulation work with the Typhoon HIL helping to ensure that all elements communicate and function as one synergistic unit.

IHI Terrasun’s customers reap the rewards of this experience in reduced project risk and lower lifetime project cost. The operational uptime, essential for any energy storage system, is maximized thanks to IHI Terrasun and Typhoon HIL’s preventive strategies.

IHI Terrasun’s SAFETM (Simulated Acceptance and Fault Emulation) Program relies on the robust fidelity of the Typhoon HIL system to validate manufacturer’s specifications and controls system operation. It’s an essential part of our solution which IHI Terrasun provides to our customers to ensure that their projects are safe, reliable and compliant with the latest grid interoperability requirements, such as IEEE2800.

Ray Saka

VP Business Strategy and Services

IHI Terrasun

IHI Terrasun Fosters Innovation

Looking ahead, as standards like IEEE 2800 become more widely mandated, the integration work conducted by IHI Terrasun on the Typhoon HIL simulation system gives project developers an advantage by providing them with a toolkit to meet these and any other emergent requirements.

The Typhoon HIL Simulation hardware, software, and tools are extremely valuable for IHI Terrasun Solutions as they provide a means to quickly, safely, and cost-effectively test Energy Storage Devices and Energy Storage Systems (ESS). This collaboration underscores IHI Terrasun’s role as a critical player in project integration and ensures the company delivers systems that meet industry standards and project requirements.

Credits

Text | Lisa Cohn, Jared Spence

Visuals | IHI Terrasun, Karl Mickei

Editor | Debora Santo