Introduction

Developing control systems has traditionally been a complex and time-intensive process, relying on document-based requirements, manual coding, and late-stage testing using physical prototypes. These traditional methods often lead to costly delays when design flaws are discovered during the integration phase, requiring extensive redesign and recoding.

Model-Based Engineering (MBE) transforms this process by adopting a model-centric approach, enabling engineers to simulate, test, and validate control software and other cyber-physical systems—both at the component and system levels—right from the start of the design process. This approach allows for early-stage design improvements, continuous testing, rapid control prototyping (RCP), and seamless integration with hardware. By adopting MBE, engineers can streamline development, reduce errors, and increase product quality in significantly less time. Moreover, integrating Hardware-in-the-Loop (HIL) testing within the MBE approach enables engineers to validate models using real hardware components within a controlled simulation environment, bridging the gap between simulation and actual physical implementation.

What Does Model-Based Engineering Look Like in Controller Development?

Model-Based Engineering (MBE) leverages digital models to manage complex systems throughout the entire lifecycle, from system specification and early-stage component-level design to development and maintenance. In controller development, MBE helps streamline and adapt different development methodologies—such as Waterfall, V-model, and agile workflows—to your needs, integrating simulation, testing, and automation at every stage.

Early in the lifecycle, engineers can create fully virtual models representing both the control systems and power stages. These simulations typically begin with a higher level of abstraction, enabling teams to evaluate design choices, assess system-level performance, and troubleshoot issues early with flexibility, without the need for real-time models or the cost and risks of physical prototypes. As the project progresses from design to development and verification, models become more detailed, and their fidelity improves. Fully virtual offline simulations can then transition to high-fidelity, real-time HIL simulations that interface with actual controllers. This step ensures the system is validated under real-world conditions, promoting robustness and efficiency. Additionally, the controller under development can be continuously tested, ensuring not only individual performance but also seamless system-level integration and interoperability.

Combining MBE with an agile approach reduces integration risks, making it easier to debug and optimize complex systems before real hardware implementation. Furthermore, digital twins — virtual replicas of the final product — can be used for ongoing maintenance, upgrades, and real-time performance monitoring.

Expanding Design Possibilities with a Fully Integrated Toolchain

Traditional workflows require engineers to manually code and test each design iteration on physical hardware, which is a slow and resource-intensive process. MBE removes these constraints by leveraging simulation, allowing teams to explore countless design variations without incurring additional costs.

In controller development, MBE typically involves various simulation approaches, starting with offline Model-in-the-Loop (MIL) in the early design phases, progressing to Software-in-the-Loop (SIL), and ultimately reaching high-fidelity Controller Hardware-in-the-Loop (C-HIL). However, integrating these approaches at different development stages can be challenging when multiple software tools are required, as maintaining separate models and platforms disrupt workflow continuity, increases costs, introduces modeling errors, and complicates version control.

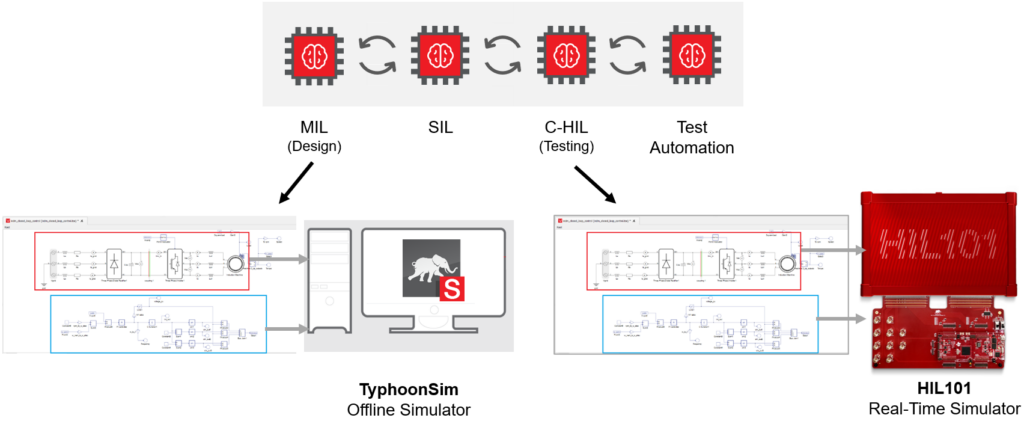

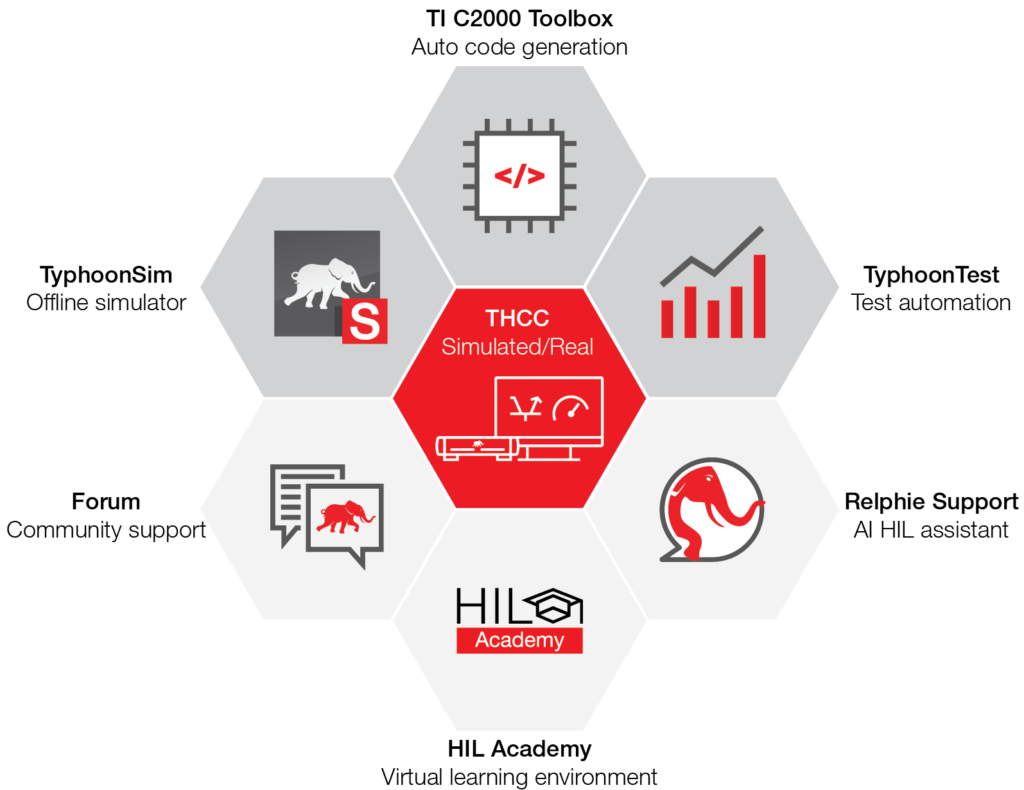

To address these challenges, Typhoon HIL’s fully integrated toolchain provides a seamless solution, enabling a smooth transition between simulation approaches while maintaining an agile approach with true model continuity throughout development. This is achieved through the combination of TyphoonSim and automatic code generation capabilities within the Typhoon HIL Control Center (THCC) software toolchain, and the flagship real-time simulators, as shown in Figure 1.

TyphoonSim | One Model. One Simulation Environment.

TyphoonSim is a high-speed offline simulator featuring variable-step capabilities, providing unparalleled flexibility for power stage and control design. Its state-of-the-art solvers enable high-speed simulations of hybrid differential equations, accurately capturing both continuous and discrete dynamics. With TyphoonSim, engineers can develop and test controllers in a fully virtual environment before deploying them to real hardware, significantly accelerating design iterations and reducing development costs. Additionally, because TyphoonSim shares the same component library as real-time HIL simulators, transitioning from offline simulations to HIL testing is seamless, ensuring consistency and reliability throughout the development process.

The integration of TyphoonSim into the development workflow empowers engineers to:

- Test and refine control strategies and power stage design before hardware deployment.

- Optimize performance under a wide range of operating conditions.

- Transition easily from offline simulations to real-time HIL testing.

- Reduce overall development time and costs while increasing test coverage.

Incorporating advanced simulation tools like TyphoonSim into model-based design allows engineers to innovate with confidence, knowing their designs have been rigorously tested before implementation.

TI C2000 Toolbox | Automatically Generate Optimized Code.

Additionally, to further support a seamless transition from offline to HIL testing, the THCC’s code generation capabilities have been enhanced by the TI C2000 Toolbox, which enables automatic code generation, compilation, and flashing for various TI target platforms from the Schematic Editor graphical user interface.

Key features of the TI C2000 Toolbox include:

- Seamless compatibility with various C2000 microcontroller devices.

- Peripheral Configuration: Easily configure peripherals to meet your application needs using Schematic Editor component library.

- Automatic Code Generation: Generate optimized code tailored to your device’s specifications.

- Integrated Workflow: Compile and flash the code directly to the DSP in one streamlined process.

- Example Models: Includes ready-to-use models to jumpstart your projects.

- Automated Testing: Validate functionality with built-in tests for example models.

- Widget library: Establish communication between HIL SCADA and DSP using specialized widgets.

Finally, Typhoon HIL offers ready-to-use interfaces, such as TI Interface Cards, to streamline the deployment of the C-HIL setups.

From Simulation to Hardware with Controller HIL (C-HIL) and Rapid Control Prototyping

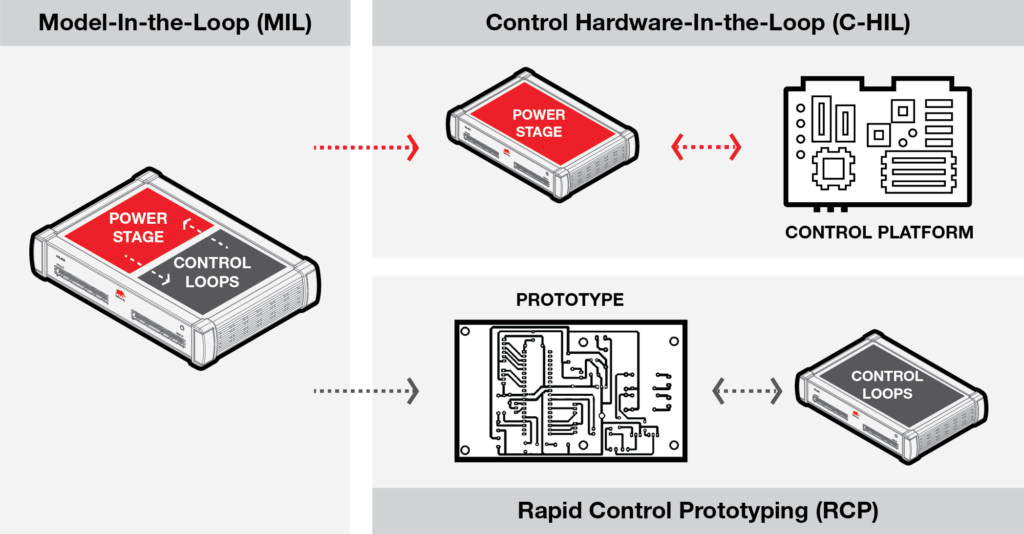

While model-based engineering allows engineers to develop and test control algorithms in a virtual environment using MIL and SIL approaches, the transition from simulation to hardware implementation is a crucial phase in real-world system development. Both RCP and C-HIL (see Fig. 2) serve as intermediate validation steps in this development process before transitioning to production-ready hardware.

RCP enables engineers to validate the real power stage hardware while keeping the controller in a real-time simulation environment. Conversely, C-HIL allows validation and testing of the controller on its final target platform (including software, firmware, and hardware) while simulating the power stage with high fidelity in real time. Both methods allow engineers to test their algorithms in a realistic hardware environment without many of the risks associated with full deployment.

C-HIL is particularly valuable in industries where control precision and safety are critical, such as renewable energy systems, power electronics, microgrids, e-Mobility, and distribution control and protection systems. By testing on the real controller prior to engaging in full power tests, the controllers can be safely validated for a wide range of conditions, including those that would otherwise be dangerous at full power.

By integrating C-HIL and/or RCP into the development workflow, engineers can:

- Validate control strategies in a hardware environment without committing to custom hardware development.

- Reduce development time by identifying and fixing errors before final deployment.

- Optimize performance and fine-tune parameters in real-time with minimal risk.

- Seamlessly transition to full HIL testing, ensuring the controller functions reliably in the final embedded system.

Enhancing Model-Based Engineering with Test Automation

Integrating test automation significantly enhances the development of controllers by streamlining validation processes and boosting overall efficiency. Unlike manual testing, which can be time-consuming and prone to human error, automated testing allows engineers to execute complex test procedures quickly and consistently. This approach not only accelerates development cycles but also ensures that control algorithms are thoroughly validated across a wide range of scenarios. Moreover, the test automation framework includes automatic report generation, which simplifies the management of complex systems while improving communication among engineers and teams.

One of the most impactful benefits of automated testing is the increased test coverage it provides. Engineers can run extensive test cases that would be impractical or impossible to perform manually, enabling comprehensive validation at every stage of development. Automation also enhances consistency by eliminating variability in test execution and delivering repeatable and reliable results—crucial for maintaining system integrity, especially in safety-critical applications.

Moreover, test automation helps shorten development timelines. By applying MBE and running tests rapidly and continuously, teams can iterate design changes faster, identify issues early, and push updates with confidence. This approach reduces debugging time and allows engineers to focus on higher-level tasks such as optimizing control strategies and refining system architecture, rather than getting bogged down by repetitive testing procedures.

To support this process, Typhoon HIL’s fully integrated toolchain offers dedicated tools that seamlessly integrate into the MBE workflows. The TyphoonTest framework and TyphoonTest IDE provide a powerful environment for automating offline simulations and real-time Hardware-in-the-Loop (HIL) testing, allowing engineers to create, execute, and analyze test scenarios with ease. For teams seeking even more advanced automation capabilities, Typhoon Test Hub extends these features by facilitating continuous integration and deployment (CI/CD) practices—ensuring that controllers are rigorously tested throughout development.

By leveraging Typhoon HIL’s test automation solutions, engineers can build robust, reliable control systems more efficiently. This combination of MBE and automation not only accelerates time-to-market but also strengthens the quality and performance of embedded controllers, empowering teams to innovate with confidence.

Conclusion

Model-Based Engineering (MBE) is transforming controller development by integrating simulation and test automation, enabling continuous validation into every stage of the process. Unlike traditional methods, MBE enables early testing and verification, helping engineers identify and resolve issues long before hardware deployment. This approach reduces design risks, accelerates iterations, and increases test coverage—ultimately driving the creation of high-performance systems.

By leveraging Typhoon HIL solutions (see Fig. 3)—TyphoonSim for offline simulation and HIL testing for real-time validation—engineers can streamline workflows, focus on system integration, and optimize control strategies with greater confidence. To bridge the gap between offline simulation and hardware implementation, automatic code generation features, and the TI C2000 Toolbox offer a powerful way to rapidly deploy real-world controllers. Finally, Typhoon HIL test automation solutions provide a flexible and powerful test framework that enables engineers to execute complex test procedures rapidly, reliably, and with unwavering consistency.

For those seeking to master these tools, the HIL Academy courses and Applications Bootcamp program provide hands-on training, equipping engineers with the practical skills needed to innovate and stay competitive. The Typhoon HIL Forum is another resource that serves as a community-based platform to troubleshoot challenges and learn from the experiences of other HIL engineers. As industries embrace digital transformation, adopting MBE will be essential for driving smarter, faster, and more reliable embedded system development.